As a beneficiation or smelting slag after the achievement of a residue, slag vertical mill grind through different fineness slag powder, humans are increasing the intensity of the resource utilization of industrial solid waste, to minimize hazards brought by industrial solid waste at the highest degree.

Slag powder equivalent amount to replace cement of concrete and cement products, can significantly improve the overall performance of concrete and cement products. Slag powder as a new high-performance concrete admixture has the advantage as following:

1. Slag powder can greatly improve the strength of concrete; can be formulated surplus of high-strength concrete;

2. Can effectively inhibit alkali-aggregate reaction of concrete, significantly improve the performance of alkali aggregate reaction of concrete and improve the durability of cement concrete;

3. Slag powder concrete can effectively improve the performance of anti-sea erosion, especially for anti-sea engineering;

4. The amount of water bleeding of cement can be significantly reduced and to improve the workability of the concrete;

5. Slag powder can significantly increase the density of concrete and improve the impermeability of concrete;

6. Slag powder can significantly reduce the heat of hydration of cement concrete, suitable for mass concrete configuration.

Slag main ingredient analysis sheet(%)

| Variety | CaO | SiO2 | Fe2O3 | MgO | MnO | Fe2O3 | S | TiO2 | V2O5 |

|---|---|---|---|---|---|---|---|---|---|

| Steelmaking, casting blast furnace slag | 32-49 | 32-41 | 6-17 | 2-13 | 0.1-4 | 0.2-4 | 0.2-2 | - | - |

| Manganese iron slag | 25-47 | 21-37 | 7-23 | 1-9 | 3-24 | 0.1-1.7 | 0.2-2 | - | - |

| Vanadium iron slag | 20-31 | 19-32 | 13-17 | 7-9 | 0.3-1.2 | 0.2-1.9 | 0.2-1 | 6-25 |

0.06-1

|

| Specification | Ultrafine and deep processing(420m³/kg) |

|---|---|

| Equipment selection program | Vertical grinding mill |

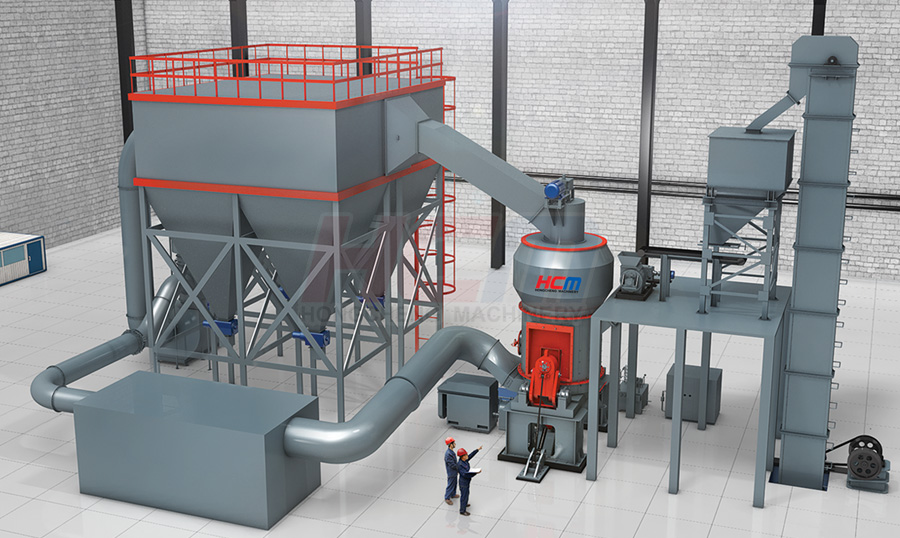

HLM vertical grinding mill can be widely used in electricity, metallurgy, cement, chemicals, non-metallic mineral industries, mainly used for grinding and processing of cement raw material, clinker, power plant desulfurization limestone powder, slag powder, manganese ore, gypsum, coal, barite , calcite, bauxite and other materials.

Phrase one: raw material crushing

Slag blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed slag material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phrase three: classifying

Ground slag powder will be classified; coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting

qualified powder will flow with the air and be collected in the dust catcher, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

Guilin Hong Cheng slag vertical mill is durable, excellent quality equipment, of which the environmental protection concept is very prominent, basically very little dust spill in workshop, the overall environment is clean and tidy, power consumption is very low, which is very important for enterprises, it directly reduce the production and operating costs, save a lot of money for powder making companies. It is truly an economical and practical vertical mill with superior performance. Currently, it is very popular in the market.

Some slag processing enterprise

Material: slag

Fineness:200mesh D90

Capacity:15-20t/h

Equipment: 1 set of HLM2100