Feldspar group minerals containing some of the alkali metal aluminum silicate mineral, feldspar belong to one of the most common feldspar group minerals, belongs to monoclinic system, usually rendered meat red, yellow, white and other colors; According to its density, hardness and composition and characteristics of the contained potassium, feldspar powder has a wide range of application in glass, porcelain and other industrial manufacturing and preparation of potash.

Feldspar powder is the main raw material for the glass industry, accounting for about 50%-60% of the total amount; in addition, accounted for 30% of the amount in ceramic industry, and other applications in chemical, glass flux, ceramic body materials, ceramic glaze, enamel raw materials, abrasives, fiberglass, welding industries.

1. One of the purposes: glass flux

The iron contained in feldspar is relatively low, easy melting than alumina, relatively speaking, K-feldspar melting temperature is low and broad category, it is often used to increase the glass batch alumina content, thereby reduce the amount of alkali in the manufacturing process of glass.

2. The second purpose: the ceramic body ingredients

Feldspar used as ceramic body ingredients, can reduce shrinkage or deformation occurs due to drying, thereby improving the drying performance and shorten the drying time of the ceramic.

3. The third purpose: other raw materials

Feldspar can also mixed with other mineral material for making enamel, also a most common painting in enameled material. Rich in potassium feldspar contained, it can also be used as raw material to extract potash.

| SiO2 | Al2O3 | K2O |

|---|---|---|

| 64.7% | 18.4% | 16.9% |

| Specification(mesh) | Ultrafine powder processing(80 mesh-400 mesh) | Deep processing of ultrafine powder(600 mesh-2000 mesh) |

|---|---|---|

| Equipment selection program | Vertical mill or pendulum grinding mill | Ultrafine grinding mill or ultrafine vertical mill |

.jpg)

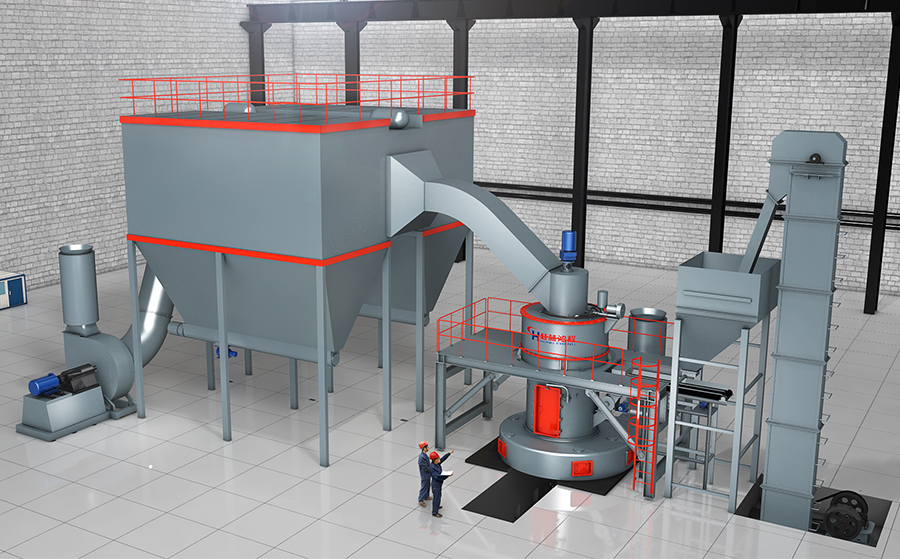

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2, HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3, HCH ultrafine grinding roller mill:ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4, HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Phrase one: raw material crushing

Feldspar blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed feldspar material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phrase three: classifying

Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting

Qualified powder will flow with the air and be collected in the dust catcher, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

Hong Cheng feldspar mill is very high operating efficiency and reliable quality, the benefits have been greatly improved since the purchase of Guilin Hong Cheng feldspar grinding mill, greatly improved the user's equipment efficiency whether in production capacity or in the unit of energy consumption, created an excellent social and economic benefits for us, can truly be called a new type of energy efficient powder milling equipment.

Some feldspar processing enterprise

Material: Feldspar

Fineness: 200mesh D97

Capacity: 6-8t/h

Configuration: 1 set of HC1700