Phosphogypsum refers to the solid waste in the production of phosphoric acid with sulfuric acid phosphate rock, the main component is calcium sulfate. Phosphorus gypsum is generally powder, the appearance is gray, grayish yellow, light green and other colors, contains organic phosphorus, sulfur compounds, bulk density 0.733-0.88g/cm3, particle diameter is generally 5 ~ 15um, the main component is calcium sulfate dihydrate, content counted about 70 ~ 90%, among which secondary ingredients contained vary with different phosphate rock origin, usually contain rock components Ca, Mg phosphate and silicate. China's current annual emissions of phosphogypsum is about 20 million tons, the cumulative displacement of nearly 100 million tons, is the largest displacement of gypsum waste, gypsum waste had occupied large number of soil and formed waste slag hill, which seriously polluted the environment.

1. Widely used in the field of building materials, large consumptive amount of phosphogypsum and its mature technology application route is carried out by grinding mill. The fine powder of gypsum plaster could be used as building materials in the manufacture of new products including gypsum instead of natural gypsum cement retarder production, refining building gypsum powder, production of plaster board, gypsum block and the like.

2. phosphogypsum rendered acidic, is very rich in sulfur, calcium, magnesium and other trace elements, in addition of widely used for construction, road and other purposes, but also for improvement of saline-alkali soil conditioner, played an important role in alleviate desertification. And moreover, phosphogypsum can also be prepared as a long-acting fertilizer and other fertilizer raw materials.

3. Phosphogypsum has a very large space for development. In industrial field, phosphogypsum used to produce sulfuric acid and cement ammonium sulfate, potassium sulfateand and other products through different processing methods, give full play to its special value.

HLM currently widely used on the market as the first choice of vertical mill for phosphogypsum grinding, because of its low power consumption, feed size, easy to adjust the product fineness; the process is simple and other advantages to activated in non-metallic mineral including gypsum market.

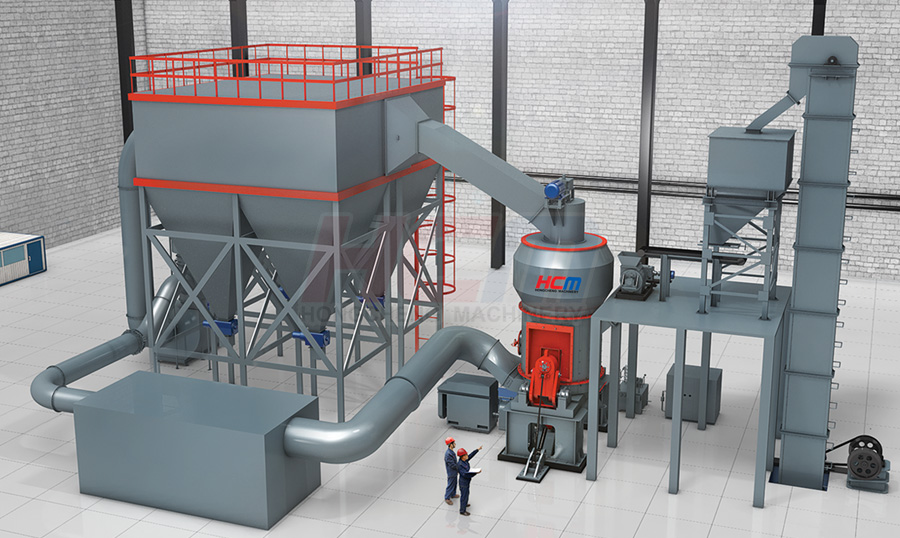

Hong Cheng vertical mill --HLM vertical milling integrate from drying, grinding, classification, transport as a whole, mainly used grinding and processing of cement, clinker, power plant desulfurization with lime powder, slag powder, manganese ore, gypsum, coal , barite, calcite and other materials. The mill mainly consist of main frame, feeder, classifier, blower, plumbing fixtures, hopper, electronic control systems, collection systems, etc., is a very advanced, efficient, energy-saving milling equipment.

Phrase one: raw material crushing

Phosphogypsum blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed phosphogypsum material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phrase three: classifying

Grinded phosphogypsum powder will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting

qualified powder will flow with the air and be collected in the dust catcher, and then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.