Petroleum coke is distillation to separate the light and heavy oils, heavy oil turn into end product by thermal cracking process. Tell from the appearance, coke is irregular in shape and sizes of black lumps (or particles) a metallic luster; coke particles having porous structure, the main elements is carbon, possession of more than 80wt%, the rest is hydrogen, oxygen, nitrogen, sulfur and metal elements. Chemical properties of petroleum coke with its unique physical and chemical properties and mechanical properties. The non-volatile carbon which is heat part of itself, volatile matter and mineral impurities (sulfur, metal compounds, water, ash, etc.), all those indicators determines coke’s chemical properties.

Needle coke: have obvious needle structure and fiber texture, majority applied as high power graphite electrode in steel-making. For needle coke has strict quality requirement in sulfur content, ash content, volatile and true density etc, so that there are special requirement for needle coke’s processing art and raw material.

Sponge coke: high chemical reactivity, low impurity content, mainly used in aluminum industry and carbon industry.

Shot coke or globular coke: cylindrical spherical shape, the diameter of 0.6-30mm, usually produced by a high-sulfur, high asphalting residue, it can only be used for power generation, cement and other industrial fuel.

Powder coke: produced through fluidized coking processing, particles are fine (diameter of 0.1-0.4mm), high volatile and thermal expansion coefficient makes it cannot be directly used in electrodes and carbon industry.

The main application areas of petroleum coke for the aluminum industry, accounting for more than 65% of the total amount of petroleum coke, followed by carbon, silicon and other industrial smelting industries, petroleum coke as fuel is mainly cement, power generation, glass, etc. industry, less proportion. At present, petroleum coke supply and demand basically the same, but due to a large number of high-sulfur petroleum coke exports, making the total lack of domestic supply of petroleum coke, still need to import high sulfur petroleum coke supplement. With the construction in recent years, a large number of coking units, the domestic production of petroleum coke will be further expanded.

The application of petroleum coke powder in glass industry:p>

1.Once the glass melting furnace ignition, it cannot be turn off until the furnace overhaul (3--5 years), it must continue to add fuel to ensure the furnace temperature stays at thousands of degrees; so that usually most of the plant will have a spare mill to ensure that continued production.

2.Petroleum coke powder used in glass industry, fineness of 200 mesh D90.

3.Raw coke moisture content of 8% -15%, it is generally needed for drying before entering the mill.

4.End petroleum powder moisture content is as good as low, generally speaking open system is better on dewatering.

Petroleum coke grinding mill selection and processing, The largest amount of petroleum coke powder making is desulfurization of power plant.

Key parameter of petroleum coke grinding

| Grindability factor | Primary moisture(%) | End moisture(%) |

|---|---|---|

| >100 | ≤6 | ≤3 |

| >90 | ≤6 | ≤3 |

| >80 | ≤6 | ≤3 |

| >70 | ≤6 | ≤3 |

| >60 | ≤6 | ≤3 |

| <40 | ≤6 | ≤3 |

1.The grindability factor of petroleum coke is an important factor to effect capacity, the lower grindability factor is, the lower capacity will be.

2.Raw material primary moisture usually is 6%. Grinding mill has to be configured with dryer or go through a hot air design is raw material moisture is over 6%, the lower of moisture can increase capacity and product quality.

Main frame selection program of petroleum coke grinding mill.

|

200mesh D90 | ||

|---|---|---|

|

1250 Vertical Roller Mill is using in Xiangfan, it is high energy consumption because of its old type and without updating for years. What customer cares is the function of get through hot air. |

||

|

Impact mill |

Market share of 80% in Mianyang, Sichuan and Suowei, Shanghai before 2009, it is eliminating now. |

Raymond mill: high investment cost, high capacity, low energy consumption, stable equipment running, low maintenance cost, the priority equipment for petroleum coke powder making.

Vertical mill: high investment cost, high capacity, high energy consumption.

Impact mill: low investment cost, low capacity, high energy consumption, high error ratio, high maintenance cost. ke powder used in glass industry, fineness of 200 mesh D90.

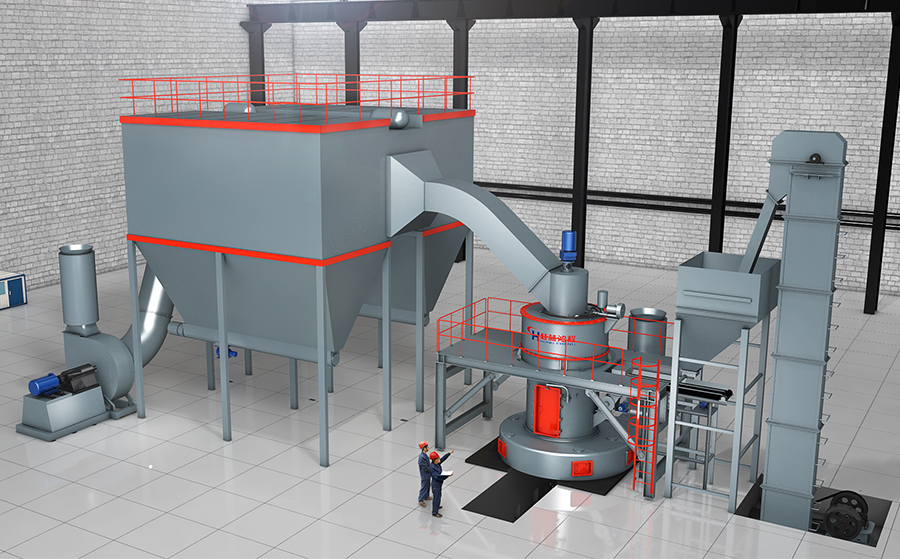

HC series grinding mill have several advantages in petroleum coke powder making

Vertical pendulum structure: strong grinding power, high capacity which is 30% than normal pendulum mill and 200% than impact mill.

High-precise in classify: product fineness has to reach 200mesh D90, higher can be 200mesh D99.

Grinding mill system is low noise, small vibration and high environmental protection performance.

Low maintenance ratio, easy maintenance, low labor cost.

The mill can go through hot air of 300°C according to processing request, to achieve drying and grinding production. (Sanxia building material case)

Note: HC1300 and HC1700 now have a market share over 90% in petroleum coke powder making area.

Phrase one: Crushing of raw material. Big petroleum coke blocks were being crushed into suitable size of grinding mill feeding which is 15-20mm.

Phrase two: Grinding. Manganese material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding. Grinding mill has to go through hot air if moisture is over 6% for drying to save dryer equipment cost and energy consumption cost.

Phrase three: classifying. Ground material will be classified; coarse powder will fall back to the main mill to be ground again.

Phrase four: production collecting. Qualified powder will flow with the air and be collected in the collector, and then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

Hongcheng brand grinding mill is high efficiency, advanced technology of classifying, secure and effective operation, overall equipment is compact process, small footprint, save workshop construction cost. The whole system is automatically controlled, remote monitoring can be configured which workers only have to operate in control room, easier operation can save labor cost. The grinding mill is stable performance, capacity can achieve expected number. Design, installation instruction, debugging and so on of this project are free provide by Hongcheng, Our capacity and efficiency have all been increased which we are fulfill satisfied.

Model & quantity: 3 sets of HC2000, 1 set of HC1700

Material: shot coke, sponge coke

Product fineness: 200 mesh D95

Capacity: shot coke HC2000 14-20t/h, HC1700 6-7t/h; sponge coke HC2000 15-20t/h, HC1700 7t/h