Limestone bases on Calcium Carbonate (CaCO3). Lime and limestone is widely applied as construction material and industrial material. Limestone can be processed into building stones or be baked into quick lime, and then add water to make slaked lime. The lime slurry and lime putty can be used as coating material and adhesive. Lime is also the majority material for glass industry. Combined with clay, after high temperature roasted, lime can be used to produce cement.

Limestone can be ground into lime powder by grinding mill. Lime powder has wide usage according to fineness:

1. 200 mesh D95 Used to produce anhydrous calcium chloride, glass and cement. Also can be used as construction material or poultry feed.

2. 325 mesh D99 Used to produce anhydrous calcium chloride and glass, or used as the white filler of rubber and paint. Also can be applied as construction material.

3. 325 mesh D99.9 Used as the filler of plastic, paint and plywood.

4. 400 mesh 99.95 Used as the filler of wire insulation layer and pitch felt, or rubber mould pressed products.

5.Power plant desulfuration Used as desulfuration absorbent.

| CaO | MgO | Al2O3 | Fe2O3 | SiO2 | so3 | Firing quantity | Lost quantity |

|---|---|---|---|---|---|---|---|

| 52.87 | 2.19 | 0.98 | 1.08 | 1.87 | 1.18 | 39.17 | 0.66 |

Remark: Limestone with high content of SiO2, Al2O3 will be harder.

| Product fineness (mesh) | 200 mesh D95 | 250 mesh D90 | 325 mesh D90 |

|---|---|---|---|

| Model selection scheme | Vertical mill or large-scale Raymond mill | ||

Power consumption: 18~25kWh/t (depending on raw material and product fineness requirement);

Select the main mill model according to capacity and fineness requirement;

Major applications: Power plant desulfuration, blast furnace solvent, etc.

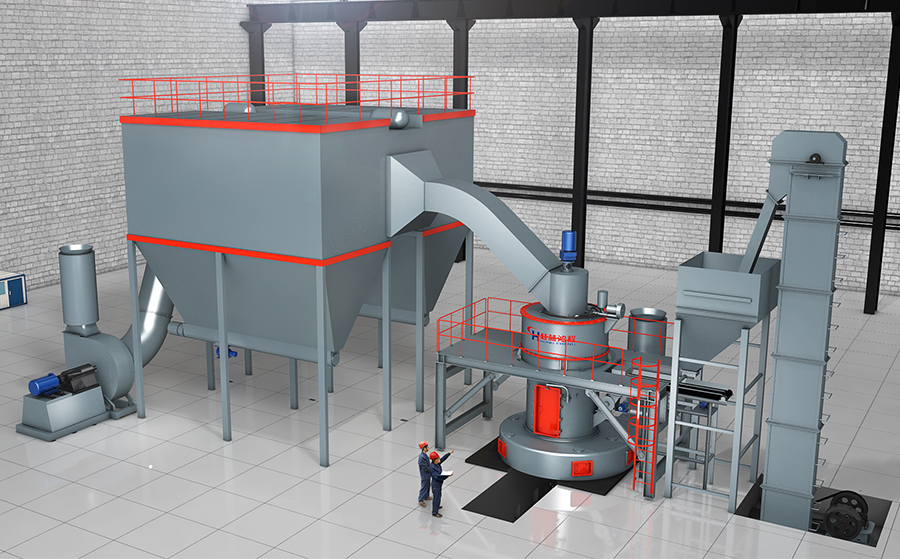

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2, HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3, HCH ultrafine grinding roller mill:ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4, HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Phase one: raw material crushing Limestone blocks will be crushed to 15mm-50mm fineness by crusher.

Phase two: grinding Lime material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding.

Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting Qualified powder will flow with the air and be collected in the collector, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

Produce the same specifications powder, HC1300 output is almost 2 tons more than the traditional 5R machine, low energy consumption. The entire system is fully automatic control; workers only need to operate in the control room, simple operation, saving labor costs. Low operating costs makes the product more competitive. And all the design, installation guidance, commissioning of the entire project are free, we are very satisfied.

Some limestone processing enterprise

Material: Limestone

Fineness: 325mesh D97

Capacity: 8-10t/h

Configuration: 1 set of HC1300