Kaolin is very pervasive in nature, is important clay minerals in modern human鈥檚 production and life, mainly formed after weathered of feldspar in igneous and metamorphic rocks or other silicate minerals, and is one of the four non-metallic minerals with mica, quartz, and calcium carbonate. Kaolin is widely used in papermaking, ceramics, refractory materials, plastics, paints, pigments, grinding wheel, cosmetics, soaps, pesticides, pharmaceuticals, textiles, petroleum, chemicals, building materials, 聽national defense and many important departments.

Natural output kaolin ores can be divided into coal kaolin, soft kaolin and sandy kaolin three categories according to the quality of content, plasticity, sandpaper. Different application areas asked for different quality requirements, such as paper coatings primarily require high brightness, low viscosity and concentration of fine particle size; ceramic industry requires good plasticity, formability and firing whiteness; Refractory demand for a high refractoriness; enamel industry requires a good suspension, etc. All this determine the kaolin specifications of product, diversity of brands. Therefore, different resources temperament, largely determine its direction of the resources available for industrial development.

Generally speaking, the domestic coal kaolin (hard kaolin), is more suitable for development as calcined kaolin, mainly used in filler aspect of different applications. Because of its high whiteness of calcined kaolin, can be used in papermaking, especially for the production of high-grade coated paper, but it is generally not used alone due to the calcined kaolin soil is mainly used to increase the whiteness, the dosage is less than washed soil in papermaking. Non-coal-bearing kaolin (soft clay and sandy clay), mainly used in paper coatings and ceramic industry.

| SiO2 | Al22O3 | H2O |

| 46.54% | 39.5% | 13.96% |

| Specification (mesh) | Fine powder 325mesh | Deep processing of ultrafine powder(600 mesh-2000 mesh) |

| Equipment selection program | Vertical grinding mill or raymond grinding mill | |

1, Raymond Mill: Raymond Mill is low investment costs, high capacity, low energy consumption, equipment is stability, low noise; is a highly efficient energy-saving mill for fine powder under 600mesh.

2, Vertical mill: large-scale equipment, high capacity, to meet the large-scale production. Vertical mill is higher stability. Disadvantages: equipment is high investment costs.

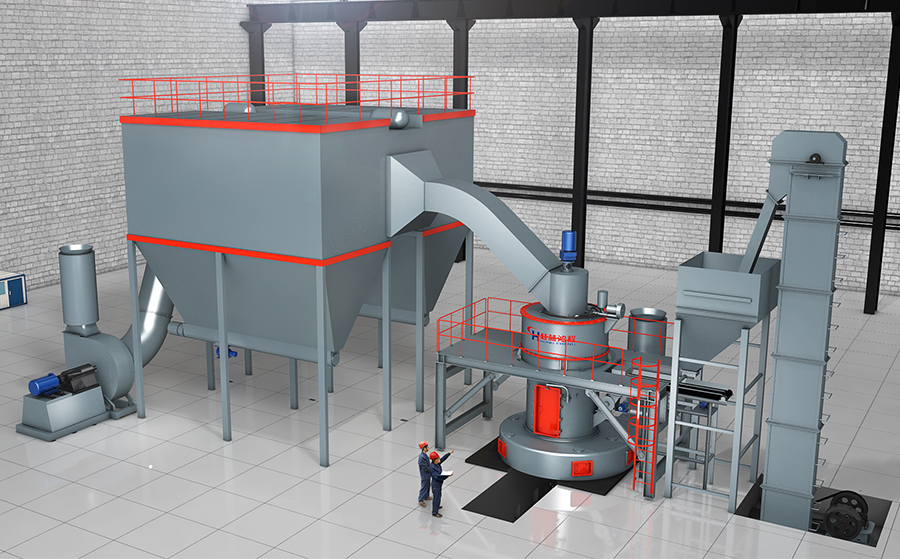

Phrase one: raw material crushing

Kaolin blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed Kaolin material will be sent to the storage hopper by the elevator and then the feeder will send the material to the main mill for grinding.

Phrase three: powder classifying

Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting

Qualified powder will flow with the air and be collected in the dust catcher, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

.jpg)

Producing powder of the same fineness, HC1300 have 2 tons higher capacity than traditional 5R mill, which lower the energy consumption. The whole system operates under full automatic control, it only need our worker to do some simple operates in the control room, which saves up labor cost. Lower cost of operating will bring more competitiveness to our production. More over, all the designing, installing and testing of the project are all free, we are very satisfied about it.

Some kaolin processing enterprise

Material: Kaolin

Fineness: 200mesh D97

Capacity: 6-8t/h

Configuration: 1 set of HC1700