Iron ore is an important industrial source, is an iron oxide ore, a mineral aggregate containing iron elements or iron compounds that can be economically utilized, and there are many types of iron ore. Among them, the iron smelting products mainly include Magnetite, siderite, and hematite and so on. Iron exists in nature as a compound, and iron ore can be gradually selected after natural iron ore is crushed, milled, magnetically selected, flotation, and reselected. Therefore, iron ore is an important raw material in the field of steel production; generally iron ore grade less than 50% needs to go through the dressing before smelting and utilization. At present, the current status of the integrated steel industry and the resource characteristics of China's iron ore resources must be continuously improved in China's metallurgical ore beneficiation process in order to promote the rapid development of the industry, equipment investment in crushing and grinding operations, production costs, electricity consumption and steel consumption and other factors will largely determine the development of the industry and market efficiency.

Main application areas of iron ore is the steel industry. In nowadays, steel products are widely used in the national economy and people's daily lives, is the basic material necessary for social production and life, steel as one of the most important structural materials in the national economy, occupies an extremely important position and has become an important pillar for social development.

Steel, steel production, variety, quality has always been a measure of a country's industrial, agricultural, national defense and science and technology an important symbol of the level of development, of which iron as the basic raw material for the steel industry, is an important raw material supporting the entire steel industry, iron ore plays a huge role in steel industry, can be smelted into pig iron, wrought iron, ferroalloy, carbon steel, alloy steel, special steel, pure magnetite can also be used as a catalyst for ammonia.

In order to give full play to the advantages of iron ore resources, in light of the characteristics of iron ore lean ore, less rich ore, more associated minerals, complex ore components and mostly finer grain size of ore ores, the ore dressing technology and ore dressing equipment need to keep pace with time, can we comprehensively improve the quality of iron ore products, quantity and comprehensive economic efficiency of enterprises.

| Ingredient\Variety | Containing Fe | Containing O | Containing H2O |

|---|---|---|---|

| Magnetite iron ore | 72.4% | 27.6% | 0 |

| Hematite iron ore | 70% | 30% | 0 |

| Limonite iron ore | 62% | 27% | 11% |

| Siderite iron ore | Main ingredient is FeCO3 | ||

| Specification | End product fineness :100-200mesh |

|---|---|

| Equipment selection program | Vertical grinding mill or Raymond grinding mill |

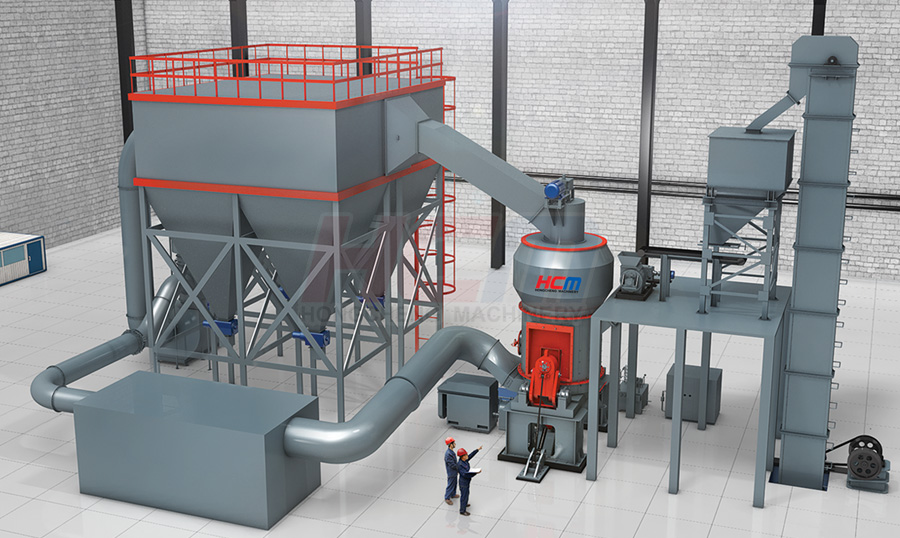

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2, HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3, HCH ultrafine grinding roller mill:ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4, HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Phrase one: raw material crushing

Iron ore blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder.

Phrase three: classifying

Ground material will be classified, coarse powder will fall back to the main mill for ground again.

Phrase four: end product collecting

Qualified powder will flow with the air and be collected by dust collector, then the finished powder will be transported to the product storage bin through discharge port. Finally, powder will be loaded by tank car or packed by packing machine.

Guilin Hong Cheng engineers are conscientious and responsible from the intention to order, field trips, production, debugging, and then to installation, not only successfully complished delivery, but also the operation of the equipment at the scene was impressive, stable running, reliable performance, production efficiency is very high, energy saving and also environmentally friendly, we are satisfied and are also very confident on Hong Cheng equipment.

Some iron ore processing plant

Equipment: 1 set of HLM21

Materials: iron ore

Finished fineness: 200 mesh D90

Capacity: 15-20t/h