Grain slag is the process of put blast furnace slag of hot melt state into water for rapid cooling, there are two ways which are blast furnace slag water quenching or pre-furnace water quenching, is an industrial solid waste, with the continuous improvement of iron production, substantial growth in the amount of slag produced, causing a lot of accumulation which it is bound to affect the development of enterprises and the social environmental governance.

Slag cement, slag aerated blocks, aerated water with residue brick are all the new application method of grain slag. It is mainly used as below:

1. Slag cement products: Portland blast furnace slag cement, gypsum slag cement, lime slag cement. Lime slag cement can be used for steam curing precast concrete products, water, underground, road and other unreinforced concrete and mortar industry and civil building mud;

2. Produce slag bricks and wet grinding slag concrete products: slag bricks, wet grinding slag concrete, aerated steam-cured brick, aerated concrete blocks, fly ash aerated brick, unburned brick, brick pad;

3. Used for insulation packing: Instead of diatomite used for heat insulation filler, can save cost;

4. The production of slag powder: blast furnace slag can be used for raw material of produce slag powder after grinding by ultra-fine mill, can be used for building materials, roads, chemical, cement, water, brick and other industries.

| Enterprise | CaO | SiO2 | Al2O3 | MgO | Fe2O3 | MnO | Ti | S | K | M |

|---|---|---|---|---|---|---|---|---|---|---|

| An Gang | 38.90 | 33.92 | 13.98 | 6.73 | 2.18 | 0.26 | 0.58 | |||

| Gan Gang | 37.56 | 32.82 | 12.06 | 6.53 | 1.78 | 0.23 | 0.46 | |||

| Ji Gang | 36.76 | 33.65 | 11.69 | 8.63 | 1.38 | 0.35 | 0.56 | 1.67 | ||

| Shou Gang | 36.75 | 34.85 | 11.32 | 13.22 | 1.38 | 0.36 | 0.58 | 1.71 | 1.08 | |

| Bao Gang | 40.68 | 33.58 | 14.44 | 7.81 | 1.56 | 0.32 | 0.50 | 0.2 | 1.83 | 1.01 |

| Wu Gang | 35.32 | 34.91 | 16.34 | 10.13 | 0.81 | - | 1.71 | 1.81 | 0.89 | |

| Ma Gang | 33.26 | 31.47 | 12.46 | 10.99 | 2.55 | - | 3.21 | 1.37 | 1.65 | 1.00 |

| Specification | End product fineness:420㎡/kg |

|---|---|

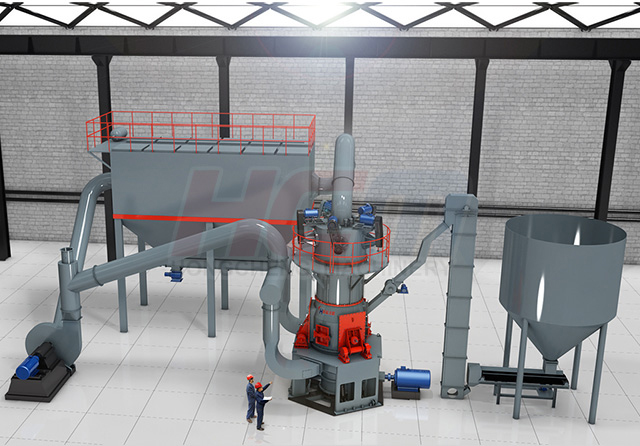

| Equipment selection program | Vertical grinding mill |

HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

Phrase one: raw material crushing

Grain slag blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed grain slag will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phrase three: classifying

Grinded grain slag powder will be classified; coarse powder will fall back into the main mill waiting to be grinded again.

Phase four: production collecting

Qualified powder will flow with the air and be collected in the dust catcher, and then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

After more than a decade of active exploration and R&D, Guilin Hong Cheng technology team finally developed a significant energy saving, low carbon and environmental protection series grain slag mill through continuous exploration and drilling. This grain slag vertical mill positive response for national call for energy-saving emission reduction policies, in line with environmentally friendly production, energy efficient production needs, provides advanced, cutting-edge, scientific and technological high-milling technology for the customer's slag milling production line, loved and welcomed by slag milling production line customers.

Some grain slag processing enterprise

Material: grain slag

Fineness: 200mesh D90

Capacity: 1520t/h

Equipment: 1 set of HLM2100