Dolomite is a kind of carbonate mineral, including ferroan-dolomite and mangan-dolomite. Dolomite is the major mineral component of dolomite limestone. Pure dolomite is white, some may be gray if contains iron.

Dolomite can be applied in construction material, ceramic, glass, refractory material, chemical, agriculture, environmental protection and energy saving fields. Dolomite can be used as basic refractory material, blast furnace flux,calcium magnesium phosphate fertilizer, and the material of cement and glass industry.

| CaO | MgO | CO2 |

|---|---|---|

| 30.4% | 21.9% | 47.7% |

Remark: usually contents silicon, aluminum, iron, titanium, etc.

| Product specification | Fine powder (80-400 mesh) | Ultra-fine deep processing(400-1250 mesh) | Micro powder(1250-3250 mesh) |

|---|---|---|---|

| Model | Raymond mill, vertical mill | Ultra-fine mill, ultra-fine vertical mill | |

.jpg)

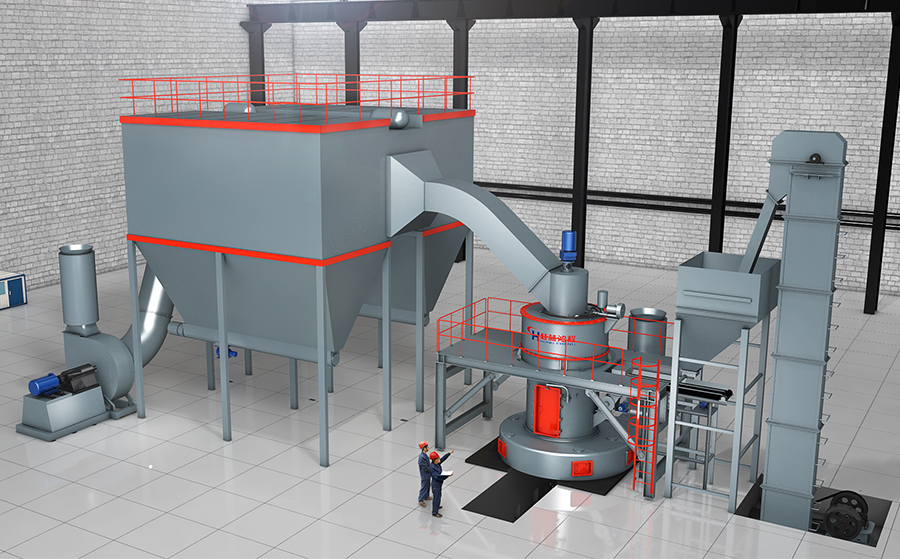

1. HC Series Grinding Mill: low investment cost, high capacity, low energy consumption, steady operation, low noise. Disadvantages: lower single capacity, not large-scale equipment.

2. HLM Vertical Mill: large-scale equipment, high capacity, steady operation. Disadvantages: higher investment cost.

3. HCH Ultra-fine Mill: low investment cost, low energy consumption, high cost-effective. Disadvantage: low capacity, multiple sets of equipment is required to build a production line.

4. HLMX Ultra-fine Vertical Mill: able to produce 1250 mesh ultra-fine powder, after equipped with multilevel classifying system, 2500 mesh micro powder can be produced. The equipment has high capacity, good production shape, is an ideal facility for high quality powder processing. Disadvantage: higher investment cost.

Phase one: raw material crushing

Dolomite blocks will be crushed to 15mm-50mm fineness by crusher.

Phase two: grinding

Dolomite material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding.

Phase three: classifying

Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting

Qualified powder will flow with the air and be collected in the collector, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

.jpg)

Hong Cheng’s complete set of equipment is compact, small footprint, saving plant costs. The entire system is fully automatic control, also can equip remote monitoring system, workers only need to operate in the control room, simple operation, saving labor costs. Mill performance is also stable, the output reached expectations. All the design, installation and commissioning of the entire project are free. Since the use of the Hong Cheng mill, we have increased production and efficiency, and we are very satisfied.

Dolomite Processing Case:

Material: Dolomite.

Fineness: 325mesh D97.

Capacity: 8-10t/h.

Configuration: HC1300.