Coal is a kind of carbonized fossil mineral. It is organized by carbon, hydrogen, oxygen, nitrogen and other elements, majority used as fuel by human. At present, the coal has 63 times of explored reserve volume than petroleum. Coal was called the black gold and the food of industry, is the major energy since the 18th century. During the Industrial Revolution, along with the invention and application of steam engine, coal is widely used as industrial fuel and brought unprecedented huge productive forces for the society.

| Category | Soft coal |

Meager coal | Lean coal |

Coking coal |

Fat coal | Gas coal | Weak bond coal | Non-bond coal | Long flame coal | Brown coal |

|---|---|---|---|---|---|---|---|---|---|---|

| Volatility | 0~10 | >10~20 | >14~20 | 14~30 | 26~37 | >30 | >20~37 | >20~37 | >37 | >40 |

| Cinder characteristics | / | 0(powder) | 0(blocks) 8~20 | 12~25 | 12~25 | 9~25 | 0(blocks)~9 | 0(powder) | 0~5 | / |

Brown coal:

Majority in blocks shape, in dark brown color, dark gloss, loosen character; containing 40% volatile component, has low ignite point, generally applied in gasification and liquidation industry, power boilers, etc.

Soft coal:

Majority in granularity, little bulk or powder, in black color with glossy, meticulous character, containing over 30% volatile component, ignite poi is not high; most soft coal is tough and is easy slagging when burned. Soft coal is widely used in coking, coal blending, power boiler and gasification industry.

Hard coal:

Blind coal is in powder or little bulk shape, in black color with shining metallic luster. The coal has low impurity, high content of fixed carbon (over 80%); the coal has low volatile component of lower than 10% and high ignite point. When burned, coal soil should be added to reduce thermal power. Blind coal can be made into coal gas or used as fuel directly.

Coal can be classified into 10 classes. Lean coal, coking coal, fat coal, gas coal, weak bond coal, non bond coal, jet coal are generally called soft coal; meager coal is called semi-anthracite coal; coal with volatile component over 40% is called brown coal. Brown coal: Majority in bar shape, in dark brown color, dark gloss, loosen character; containing 40% volatile component, has low ignite point, generally applied in gasification and liquidation industry, power boilers, etc. Soft coal: Majority in granularity, little bulk or powder, in black color with glossy, meticulous character, containing over 30% volatile component, ignite poi is not high; most soft coal is tough and is easy slagging when burned. Soft coal is widely used in coking, coal blending, power boiler and gasification industry. Blind coal: Blind coal is in powder or little bulk shape, in black color with shining metallic luster. The coal has low impurity, high content of fixed carbon (over 80%); the coal has low volatile component of lower than 10% and high ignite point. When burned, coal soil should be added to reduce thermal power. Blind coal can be made into coal gas or used as fuel directly.

| 200 mesh D80-90 | Raymond mill | Capacity<20T/h, with better cost-effective |

|---|---|---|

| Vertical mill | Capacity>20T/h, with better performance |

Remarks:

1. Power consume: 20-24Kw/h, according to raw material and product requirement;

2. Advantages of vertical mill: stable operation, saving energy and label cost;

3. Select the equipment according to capacity and fineness requirement;

4. Major application: heating power coal powder.

| HC1300 | HC1700 | HC2000 | |

|---|---|---|---|

| Capacity (t/h) | 3-5 | 8-12 | 15-20 |

| Main mill motor (kw) | 90 | 160 | 315 |

| Blower motor (kw) | 90 | 160 | 315 |

| Classifier motor (kw) | 15 | 22 | 75 |

| Model | HLM1300MF | HLM1500MF | HLM1700MF | HLM1900MF | HLM2200MF | HLM2400MF | HLM2800MF |

|---|---|---|---|---|---|---|---|

| Capacity (t/h) | 13-17 | 18-22 | 22-30 | 30-40 | 40-50 | 50-70 | 70-100 |

| Material moisture | ≤15% | ||||||

| Product fineness | D80 | ||||||

| Product moisture | ≤1% | ||||||

| Main motor power (kw) | 160 | 250 | 315 | 400 | 500 | 630 | 800 |

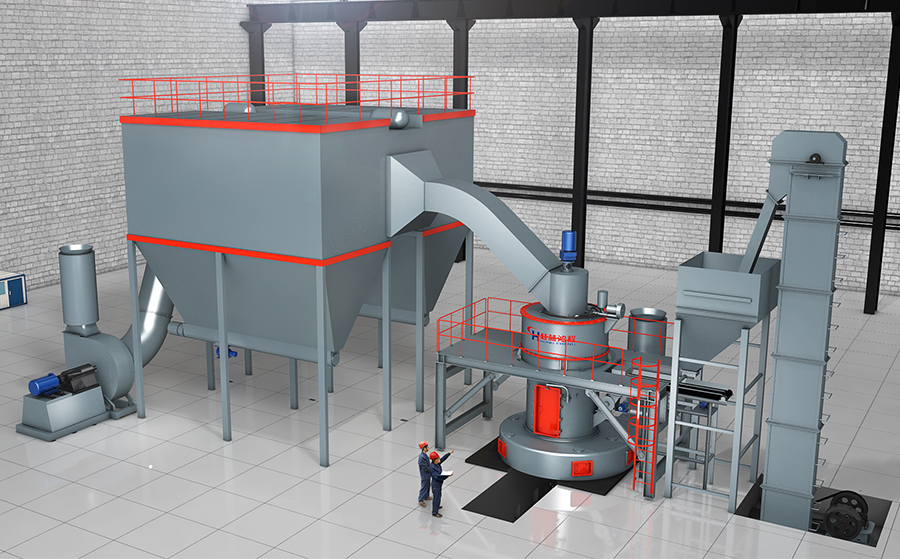

1. Pendulum mill (HC, HCQ Series Coal Mill): low investment cost, high capacity, low energy consumption, stable, low noise; but, with higher operating and maintenance cost than vertical mill.

2. Vertical coal mill (HLM Vertical Coal Mill): high capacity, large-scale production, easy maintenance, high automatic level, advanced technology. Disadvantages are high investment cost and large floor space.

Phrase one: raw material crushing Coal blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: drying and grinding 1.Coal material with low moisture will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding. The hot air in the mill will dry the coal. This will reduce drying cost. 2.For high moisture material, a dryer should be applied to dry the coal before grinding.

Phrase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phrase four: production collecting Qualified powder will flow with the air and be collected in the dust catcher, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

HC1700 Grinding Mill has open circuit system and explosion-proof device, and has 30%-40% higher capacity than traditional Raymond Mill. The whole system is under full automatic control, the easy operation saves up large operating cost. The high-tech equipment brought us large benefit, we are very satisfied with it.

Some coal processing plant

Material: blind coal

Product fineness: 200 mesh D92

Capacity: 8-12t/h.

Model & quantity: 3 sets of HC1700 Open Circuit Grinding Mills