Cement clinker is the semi-finished products based on limestone and clay, iron raw materials as the main raw material, formulated into raw materials according to the appropriate ratio, burning until part or all of the molten, and obtained after cooling. In cement industry, the principal chemical components of the most commonly used Portland cement clinker are calcium oxide, silica and small amounts of alumina and iron oxide. The main mineral composition is tricalcium silicate, dicalcium silicate, tricalcium aluminate and iron aluminate tetracallic acid, Portland cement clinker plus appropriate amount of gypsum after grinding can be made into portland cement.

At present, cement clinker is widely used in civil and industrial construction projects, such as cementing of oilfields and gas fields, large-volume dams in water conservancy projects, military repair projects, as well as acid and refractory materials, injection in tunnels cap instead of pit. In addition, wood and steel can be used instead of wood for a variety of applications such as telephone poles, railroad sleepers, oil and gas pipelines, and oil storage and gas storage tanks.

| CaO | SiO2 | Fe2O3 | Al2O3 |

|---|---|---|---|

| 62%-67% | 20%-24% | 2.5%-6.0% | 4%-7% |

| Specification | 220-260㎡/kg(R0.08≤15%) |

|---|---|

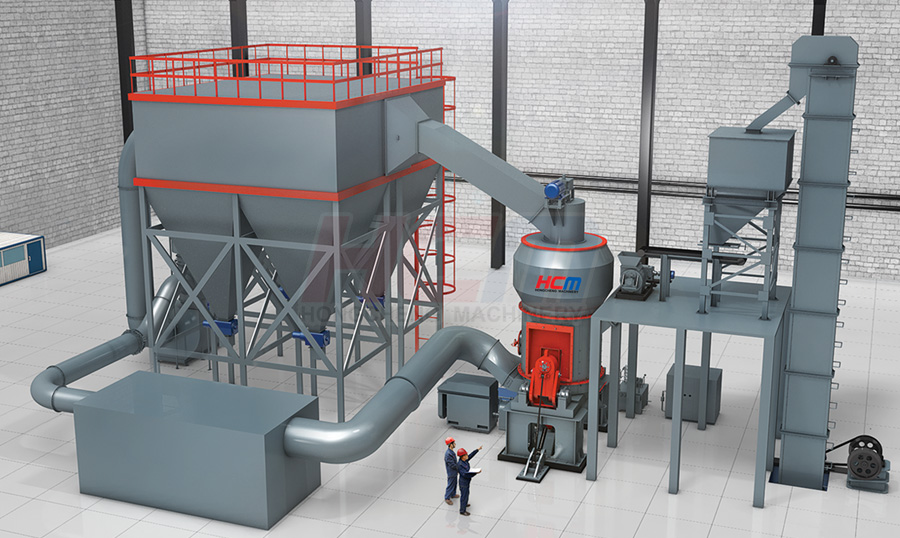

| Equipment selection program | Vertical grinding mill |

1, HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

Phrase one: Cement clinker crushing

Cement clinker blocks will be crushed to 15mm-50mm fineness by crusher.

Phrase two: grinding

Crushed cement clinker will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phrase three: classifying

Grinded cement raw material powder will be classified; coarse powder will fall back into the main mill waiting to be grinded again.

Phase four: production collecting

Qualified powder will flow with the air and be collected in the dust catcher, and then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

Guilin Hong Cheng cement clinker vertical mill is durable, excellent quality equipment, of which the environmental protection concept is very prominent, basically very little dust spill in workshop, the overall environment is clean and tidy, power consumption is very low, which is very important for enterprises, it directly reduce the production and operating costs, save a lot of money for powder making companies. It is truly an economical and practical vertical mill with superior performance. Currently, it is very popular in the market.

Some cement clinker processing enterprise

Material: cement clinker

Fineness:

Capacity:

Equipment: