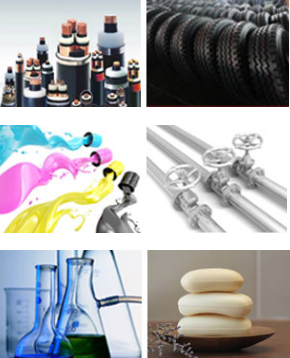

1.Under 200 mesh: used in feed supplement, calcium content more than 55.6%, without harmful component.

2.250-300 mesh: used as the raw material of plastic plant, rubber plant, coating plant, waterproof material plant, and can be also used for wall painting. Whiteness is higher than 85 degree.

3.350-400 mesh: used to produce buckle, pipe, and applied in chemical industry. Whiteness above 93 degree.

4.400-600 mesh: used to produce toothpaste and soap. Whiteness over 94 degree.

5.Over 800 mesh: used to produce rubber, plastic, cable and PVC. Whiteness over 94 degree. 6.Over 1250 mesh: applied in PVC, PE, paint, coating level production, paper making first coat and top coat with whiteness higher than 95 degree. Have the advantages of high purity, high whiteness, non-poisonous, odorless, low thin oiliness, low hardness.

| CaO | MgO | Al2O3 | Fe2O3 | SiO2 | Firing quantity | Grinding work index (kWh/t) |

|---|---|---|---|---|---|---|

| 53-55 | 0.30-0.36 | 0.16-0.21 | 0.06-0.07 | 0.36-0.44 | 42-43 | 9.24 (Moh’s:2.9-3.0) |

| Product Specification (mesh) | 80-400 | 600 | 800 | 1250-2500 |

|---|---|---|---|---|

| Model Selection scheme | R Series Grinding Mill HC Series Grinding Mill HCQ Series Grinding Mill HLM Vertical Mill | R Series Grinding Mill HC Series Grinding Mill HCQ Series Grinding Mill HLM Vertical Mill HCH Series Ultra-fine Mill | HLM Vertical Mill HCH Series Ultra-fine Mill+classifier | HLM Vertical Mill (+classifier) HCH Series Ultra-fine Mill |

Depending on material feature and production usage, different models have special advantages under different fineness requirement.

1, Raymond Mill, HC series pendulum grinding mill: low investment costs, high capacity, low energy consumption, equipment stability, low noise; is the ideal equipment for wollastonite powder processing. But the degree of large-scale is relatively lower compared to vertical grinding mill.

2, HLM vertical mill: large-scale equipment, high capacity, to meet the large-scale production demand. Product has high degree of spherical, better quality, but the investment cost is higher.

3, HCH ultrafine grinding roller mill:ultrafine grinding roller mill is efficient, energy-saving, economical and practical milling equipment for ultrafine powder over 600 meshes.

4, HLMX ultra-fine vertical mill: especially for large-scale production capacity ultrafine powder over 600 meshes, or customer who has higher requirements on powder particle form, HLMX ultrafine vertical mill is the best choice.

Phase one: raw material crushing Calcite blocks will be crushed to 15mm-50mm by crusher.

Phase two: grinding Crushed calcite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding.

Phase three: classifying Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting Qualified powder will flow with the air and be collected in the dust catcher, and then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

Material: calcite

Fineness: 325 mesh D97

Capacity: 8-10t/h

Model: 1 set of HC1300 mill