Bentonite also known as clay rock, albedle, sweet soil, bentonite, clay, white mud, vulgar name is Guanyin soil. Montmorillonite is the main component of the clay minerals, its chemical composition is quite stable, known as "universal stone." Montmorillonite is a two-layer co-connected silicon oxide tetrahedron film laminated layer of common aluminum (magnesium) oxygen (hydrogen) octahedral sheet, constitute 2: 1 type of crystal water containing silicate minerals. It is one of the most powerful minerals in the clay mineral family. Montmorillonite is a mineral belonging to the montmorillonite family, and a total of 11 montmorillonite minerals are found. They are slippery bentonite, bead, lithium bentonite, sodium bentonite, bentonite, zinc Bentonite, sesame soil, montmorillonite, chrome montmorillonite and copper montmorillonite, but from the internal structure can be divided into montmorillonite (octahedral) and the Benton subfamily (38 Surface). Montmorillonite is one of the typical layered silicate minerals, unlike other layered silicate minerals; the gap between the layers is particularly large, so that the layers and layers contain an amount of water Molecules and exchangeable cations. The results of slow scanning by diffractometer shows that the particle size of montmorillonite is close to nanometer scale and is a natural nanomaterial.

Purified lithium bentonite:

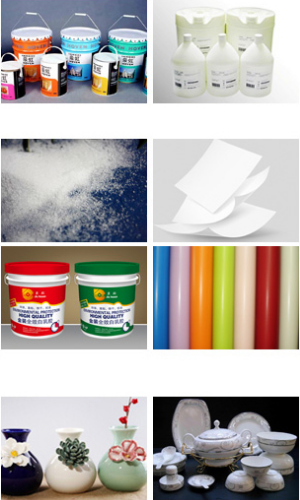

Mainly applied in foundry coating and color ceramic coating, also applied in emulsion paint and fabric sizing agent.

Purified sodium bentonite:

1.Applied as foundry molding sand and binder in machinery industry to increase casting accuracy;

2.Applied as filler in paper-making industry to increase product brightness;

3.Applied in white emulsion, floor glue and paste producing for high adhesive property;

4.Applied in water-based paint for steady suspension property and consistence.

5.Applied for drilling fluid.

Cement bentonite:

Applied in cement processing, bentonite can increase product appearance and performance.

Efficient activated clay:

1.Used for animal and vegetable oil refining, able to remove harmful composition in edible oil;

2.Used for petroleum and mineral refining and purifying;

3.In food industry, used as clarifying agent of wine, beer and juice;

4.Applied as catalyst, filler, drying agent, adsorbent and flocculating agent in chemical industry;

5.Can be applied as chemical defense antidote in national defense and chemical industry. Along with the development of society and science, activated clay will have a wider application.

Calcium bentonite:

Can be applied as foundry molding sand, binder and radioactive waste absorbent;

Also can be used as thinner and pesticide in agriculture.

| Product fineness | 200 mesh D95 | 250 mesh D90 | 325 mesh D90 |

|---|---|---|---|

| Model selection scheme | HC Series Large-scale Bentonite Grinding Mill | ||

.jpg)

Raymond mill: low capacity but high cost, large floor space, high investment cost, high failure rate and high maintenance cost.

HC Bentonite Grinding Mill: large-scale equipment, high capacity; model selection according to bentonite material character, so the stability will be high and maintenance cost will be low; the special hot-air function will largely reduce drying facility cost and energy cost.

Phase one: raw material crushing

Bentonite blocks will be crushed to 15mm-50mm fineness by crusher.

Phase two: grinding

Crushed bentonite material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding.

Phase three: classifying

Ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting

Qualified powder will flow with the air and be collected in the dust catcher, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

.jpg)

Produce the same specifications powder, HC1300 output is almost 2 tons more than the traditional 5R machine, low energy consumption. The entire system is fully automatic control; workers only need to operate in the control room, simple operation, saving labor costs. Mill performance is also stable, the output reached expectations. All the design, installation and commissioning of the entire project are free. Since the use of the Hong Cheng mill, we have increased production and efficiency, and we are very satisfied.

Some bentonite processing enterprise

Material: Bentonite

Fineness: 325mesh D90

Capacity: 8-10t/h

Configuration: 1 set of HC1300